High Performance Inking Roller for UV printing

Comparing to our conventional UV rubber, Avant UV is designed to have higher impact resilience which improves efficiency of kneading of inks and ink transfer.

* Ink transfer comparison (Close up picture x25)

|

|

|

| AVANT UV | Conventional Rubber | Other company’s rubber |

As shown above, white spots are not seen with AVANT UV. AVANT UV provides excellent ink transfer in order to achieve high quality printing.

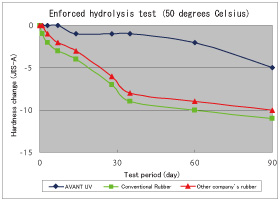

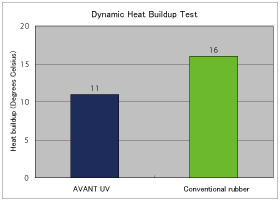

AVANT UV has minimal heat buildup, which prevents hardness decrease and increase of stickiness that are often seen for resin rollers in high speed, long runs.

The Enforced Hydrolysis Test at 50 degrees Celsius below shows that AVANT UV has extremely small deterioration.

The Dynamic Heat Buildup Test below shows that AVANT UV has less heat buildup compared to the conventional rubber.

Compared to the conventional resin rollers, roller cleaning time can be saved for AVANT UV as it has superior resistance to cleaning solvents and its roller surface is designed to be easy-to-clean.

| AVANT UV | AVANT UV | |

|

Cleaned after ink apply |

|

| Before use | Almost no ink remained |

AVANT UV is very easy to clean.

| Conventional product | Conventional product | |

|

Cleaned after ink apply |

|

| Before use | Ink remained |

AVANT UV is designed especially for use in UV printing. Printing defect can be minimized due to the improved anti ink blockage property and ink dryness on the roller surface.

As AVANT UV has excellent UV ink resistance, it shows minimal nip change with UV inks. It is very stable for extended periods.

Even when you install a brand new Avant UV or switching ink from UV to Conventional, you don’t need to take time for a break-in operation which conventional rubber needed. You can start printing right away after installation.

* Application: Offset printing, Label printing, Business form printing, Metal printing etc.

* Hardness (Shore A): 15・20・25・30・35・40・50・55・60

* Color: Light Blue

PRODUCTS

Katsura Roller Mfg. Co., Ltd.

5-3-13 Nakagawa Ikuno-ku

Osaka 544-0005 Japan

TEL +81-6-6751-1121

FAX +81-6-6754-4400

HOME | NEWS & TOPICS | PRODUCTS | ABOUT US | ABOUT ROLLERS | JOBS | NET WORK | CONTACT | SITE MAP | PRIVACY POLICY

Copyright © 2010 Katsura Roller Mfg.Co.,Ltd. All rights reserved.