Best inking roller for soy oil based inks!

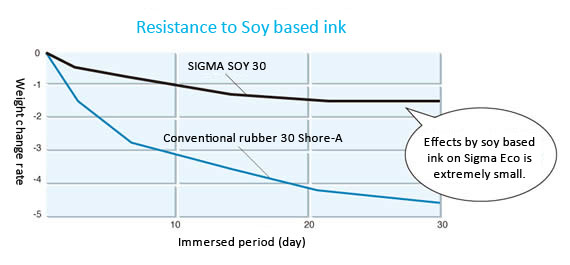

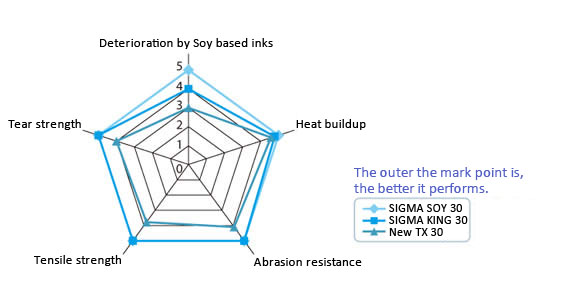

Compared to conventional inks, soy oil based inks more likely gives harmful effects to rubber rollers such as hardness increase, rubber shrinkage and so on. As a result, operator would have to adjust the nip-width often and the lifetime of the rubber roller would also become shorter.

SIGMA SOYovercomes such problems so that operators can comfortably handle inking rollers with soy based inks.

* Hardness (Shore A): 25・30・35・40

* Color: Orange

(Based on diameter change and nip width)

PRODUCTS

Katsura Roller Mfg. Co., Ltd.

5-3-13 Nakagawa Ikuno-ku

Osaka 544-0005 Japan

TEL +81-6-6751-1121

FAX +81-6-6754-4400

HOME | NEWS & TOPICS | PRODUCTS | ABOUT US | ABOUT ROLLERS | JOBS | NET WORK | CONTACT | SITE MAP | PRIVACY POLICY

Copyright © 2010 Katsura Roller Mfg.Co.,Ltd. All rights reserved.